Lime Slaking Equipment Manufacturers: The Behind-the-Scenes Heroes of Industrial Transformation

In industrial production, lime slaking is a crucial process, and lime slaking equipment manufacturers are the unsung heroes behind it. The equipment they design and manufacture not only drives the modernization of lime slaking technology but also provides efficient and environmentally friendly solutions for industries such as construction, environmental protection, and chemical manufacturing. Today, let’s explore how these manufacturers are reshaping the landscape of industrial production through technological innovation.

The Core Role of Lime Slaking Equipment

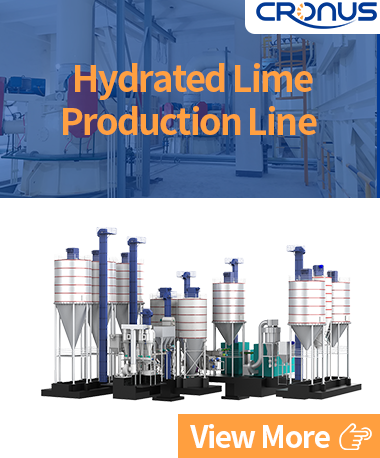

Lime slaking equipment is the key carrier for the chemical reaction between quicklime (CaO) and water (H₂O). Its core function is to control the temperature, water volume, and reaction time to ensure that quicklime is fully converted into slaked lime (Ca(OH)₂). While this process may seem simple, it places extremely high demands on the precision and stability of the equipment.

Modern lime slaking equipment typically includes the following key components:

- Feeding System: Precisely controls the ratio of quicklime to water.

- Reaction Tank: Provides sufficient space for the reaction, ensuring thorough contact between lime and water.

- Mixing System: Promotes uniform reaction and prevents lime clumping.

- Cooling System: Regulates reaction temperature to avoid overheating and equipment damage.

- Automated Control System: Monitors the reaction process in real-time to ensure consistent product quality.

The performance of this equipment directly determines the efficiency of lime slaking and the quality of slaked lime, making the technical expertise of manufacturers critical.

Technological Innovation: From Manual to Fully Automated

Early lime slaking relied heavily on manual operations, which were not only inefficient but also posed safety risks. With the development of industrial automation technology, lime slaking equipment manufacturers have gradually introduced semi-automatic and fully automated equipment, revolutionizing the industry.

Modern fully automated lime slaking equipment can achieve the following functions:

- Precise Proportioning: Uses sensors and control systems to accurately adjust the ratio of quicklime to water.

- Efficient Reaction: Optimizes reaction tank design to shorten slaking time and improve production efficiency.

- Energy Saving and Environmental Protection: Recycles heat generated during the reaction to reduce energy consumption.

- Remote Monitoring: Utilizes IoT technology to enable remote control and fault diagnosis of equipment.

These technological innovations have not only improved production efficiency but also reduced labor costs and environmental pollution, providing strong support for sustainable industrial development.

Application Fields: From Construction to Environmental Protection

The products of lime slaking equipment manufacturers are widely used in various fields:

- Construction Industry: Slaked lime is a key ingredient in preparing lime paste and mortar, used for wall construction and plastering.

- Environmental Protection Industry: Slaked lime is used in wastewater treatment and flue gas desulfurization, effectively neutralizing acidic substances and purifying the environment.

- Chemical Industry: Slaked lime is an important intermediate for producing bleaching powder, calcium carbonate, and other chemicals.

- Metallurgical Industry: Used in ore refining and metal surface treatment.

In these fields, the performance of lime slaking equipment directly impacts the quality and cost of the final products. Therefore, manufacturers need to provide customized solutions based on the specific needs of their clients.

Future Outlook: Intelligence and Green Development

With the advancement of Industry 4.0 and carbon neutrality goals, lime slaking equipment manufacturers are moving toward intelligence and green development:

- Intelligence: Through artificial intelligence and big data technology, equipment can achieve self-learning and optimization, further improving production efficiency and product quality.

- Green Development: Developing low-energy, low-emission equipment to reduce environmental impact and support carbon neutrality goals.

- Globalization: Expanding into international markets to provide high-quality lime slaking solutions to global customers.

Lime slaking equipment manufacturers are not only supporters of industrial production but also leaders in technological innovation. Their efforts are injecting new momentum into industrial transformation.

Lime slaking equipment manufacturers may not be widely known to the public, but their work profoundly impacts our daily lives. From construction to environmental protection, from chemical manufacturing to metallurgy, their equipment is everywhere. These behind-the-scenes heroes are driving industrial progress through technological innovation and contributing to sustainable development.

In the future, as technology continues to advance, lime slaking equipment manufacturers will keep leading industry transformation, bringing more possibilities to the world. Let’s give a round of applause to these dedicated manufacturers!