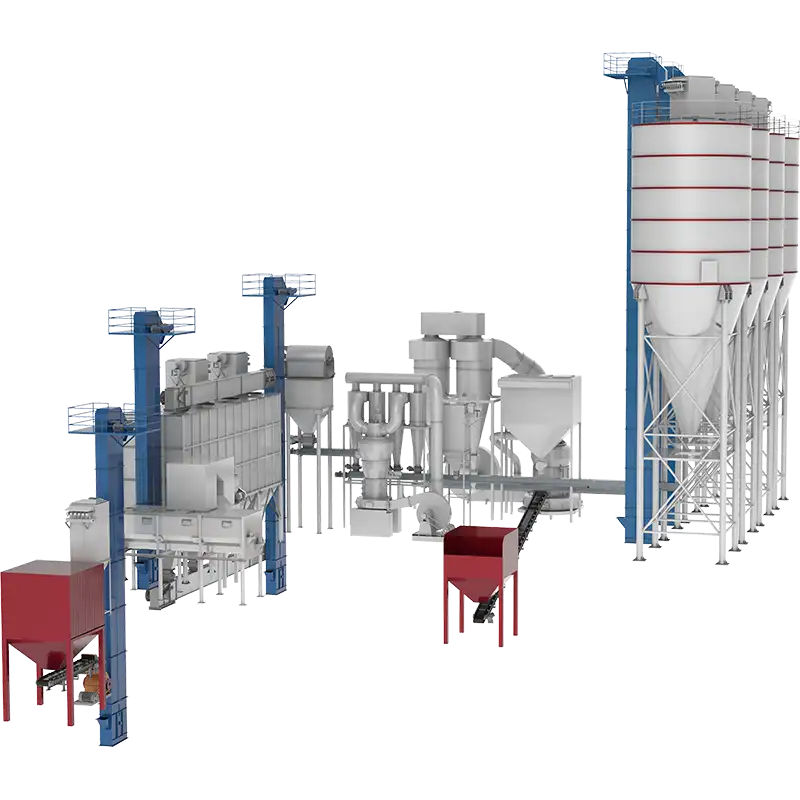

Performance and advantages of calcium hydroxide production line equipment

Calcium hydroxide, as an important inorganic chemical product, plays an indispensable role in building materials, environmental protection, water treatment and many industrial fields. As the core facility for producing this key raw material, the performance and advantages of calcium hydroxide production line equipment directly determine the quality and production efficiency of the product.

Advanced technology, the foundation of quality

CRW production line adopts a unique integrated process flow, from the fine screening and pretreatment of raw materials to the core calcination, digestion and precise grading and packaging, each link is closely connected and meticulous. In the calcination stage, the advanced energy-saving vertical kiln technology is used to accurately control the temperature and airflow distribution, so that the limestone can be fully and efficiently decomposed, which not only greatly improves the quality of calcium oxide production, but also significantly reduces energy consumption. Compared with traditional processes, the energy utilization rate is improved.

Entering the digestion stage, the high-efficiency digester independently developed by CRW plays a key role. Its innovative structural design promotes rapid and full mixing of calcium oxide and water under optimal reaction conditions to ensure that the digestion reaction is thorough. With the precise water-cement ratio automatic control system, the reaction parameters can be adjusted in real time according to the characteristics of the raw materials, and high-purity and highly active calcium hydroxide products can be stably produced, effectively avoiding product quality differences caused by manual operation fluctuations, and the calcium hydroxide content of the product is stable and maintained far above the industry average.

High level of intelligence and automation

The CRW calcium hydroxide production line equipment performs well in intelligence and automation. The equipment is equipped with advanced PLC control systems and intelligent sensors, which can realize remote monitoring and intelligent adjustment of the production process. Operators can intuitively understand the production status through the automatic control screen and make corresponding adjustments and optimizations.

In addition, the production line also has fault detection and alarm functions, which can promptly detect and handle abnormal situations in the production process to ensure the stable operation of the production line. This highly intelligent and automated production method not only improves production efficiency and quality stability, but also reduces labor costs and labor intensity.

Customized service to meet diverse needs

The CRW calcium hydroxide production line equipment also has strong flexibility and scalability. The equipment can be customized and adjusted according to the needs and production scale of different customers to meet the diverse needs of different industries for calcium hydroxide products.

At the same time, the production line also reserves interfaces and space for upgrading and expansion, which is convenient for enterprises to upgrade equipment and expand production capacity in the future according to market demand and technological development. This flexibility and scalability enables the calcium hydroxide production line equipment to adapt to the ever-changing market environment and customer needs.

Green and environmentally friendly, practicing sustainable development

CRW calcium hydroxide production line incorporates the concept of green development throughout the entire design and production process. In terms of dust control, it is equipped with a multi-stage water mist dust removal device. From raw material transportation, processing to finished product packaging, each dust-generating point is equipped with a sealed cover and dust suction duct. The collected dust is processed by advanced pulse bag dust collectors and cyclone dust collectors to ensure that the dust content in the exhaust gas is far lower than the environmental protection standard, effectively reducing pollution to the surrounding environment.