Industrial Carbon Black Grinding Mill & Impact Crusher: Key Equipment for Efficient Processing

Limestone is a widely used industrial raw material, mainly used in construction, cement, metallurgy, and chemical industries. In the mining and processing of limestone, crushing equipment plays a vital role. The main task of crushing equipment is to break large pieces of limestone into smaller pieces suitable for subsequent processing, thus laying the foundation for screening, grinding, or other processing steps. Similarly, in industries like carbon black processing, the Industrial Carbon Black Grinding Mill performs a critical function by finely grinding carbon black into the desired particle size for various applications. Both limestone crushing equipment and the Industrial Carbon Black Grinding Mill are essential for transforming raw materials into usable forms, ensuring efficient production processes and high-quality end products.

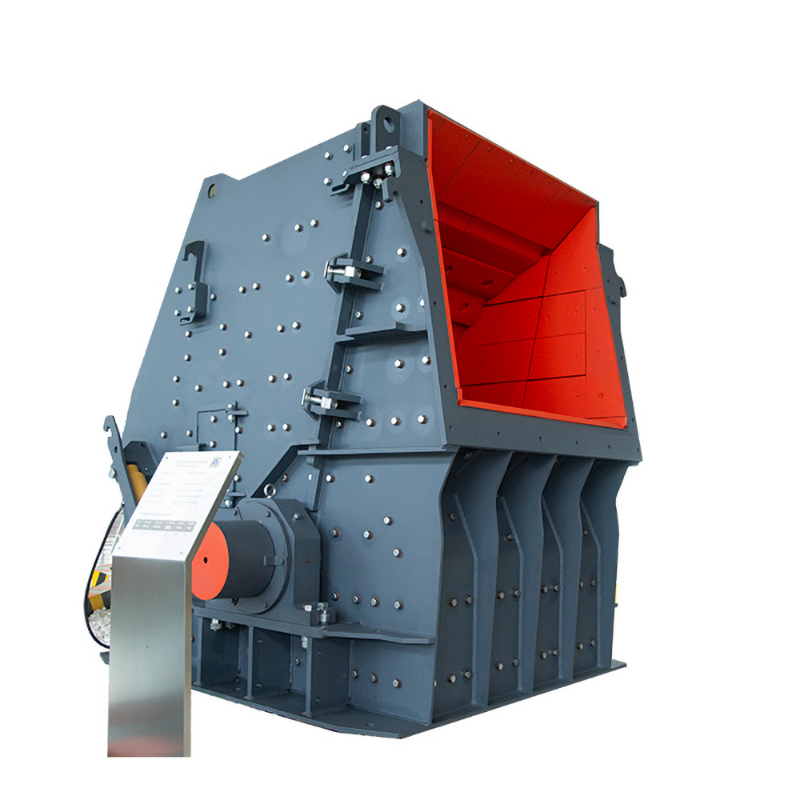

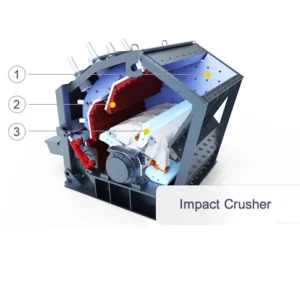

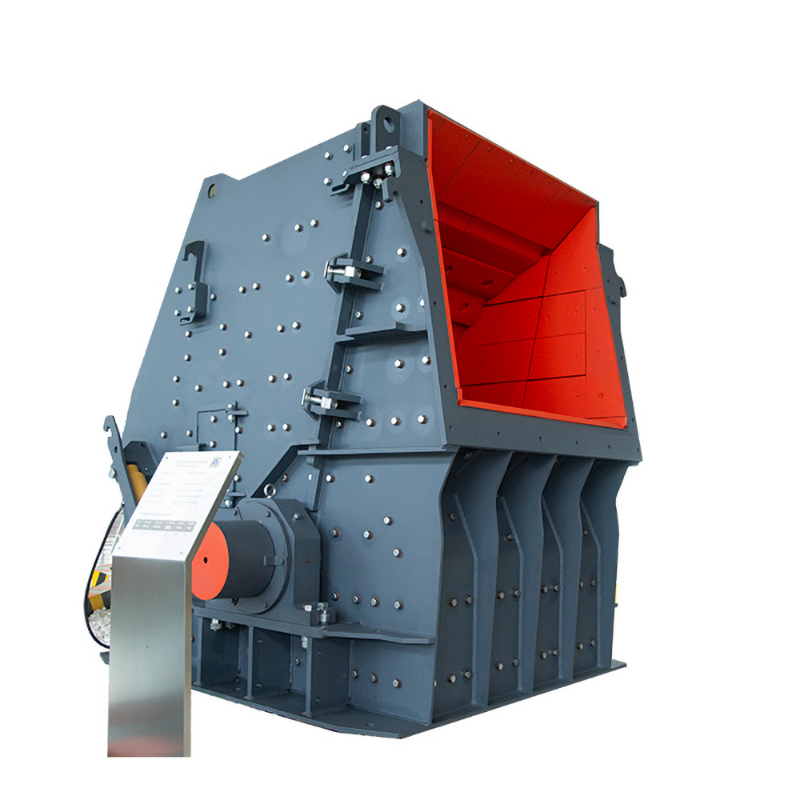

The feed size of a limestone impact crusher ranges from 100-500mm, and the desired particle size can be achieved by adjusting the gap between the hammer and impact plate. Each model of limestone impact crusher has unique parameters, including feed port size, maximum feed size, production capacity, power, weight, and volume. When selecting a model, consider factors like processed stone size, finished product requirements, hourly production, energy consumption, and investment cost to ensure optimal performance without overcapacity.

High efficiency and stability, easy operation, excellent output

The output of the equipment is another important indicator of the quality of the equipment. A good limestone impact crusher has a larger processing capacity, higher quality finished products, greater market demand, and greater economic benefits.

The processing capacity of the limestone impact crusher is generally between 30-550t/h, which can meet the general processing needs of users.

If you need a limestone impact crusher with a larger output, you can consult our Cronus for customized production.

Equipment quality

High-quality limestone impact crushers run smoothly, have low failure rates, and have long service life during use, which can effectively reduce equipment maintenance costs and downtime, ensure high-yield operation of equipment, and bring higher production benefits to users.

The components of limestone impact crushers mainly include impact blocks, plate hammers, rotors, threaded sleeves, side linings, frame components, impact racks, impact plate adjustment devices, etc. Among them, impact blocks and linings are the most easily worn parts in the entire equipment. Therefore, they need to be made of highly wear-resistant materials to ensure strong toughness and pressure resistance.

cronus is a direct sales manufacturer specializing in the production of large-scale mining machines. It has rich experience and strong strength. The equipment it produces is reliable in quality, affordable, and has a good reputation among users. Users who are interested in limestone impact crushers can consult cronus, and professional technicians will serve you online in real time.