High-efficiency calcium hydroxide production line unveiled, boosting environmental protection and high-end market development

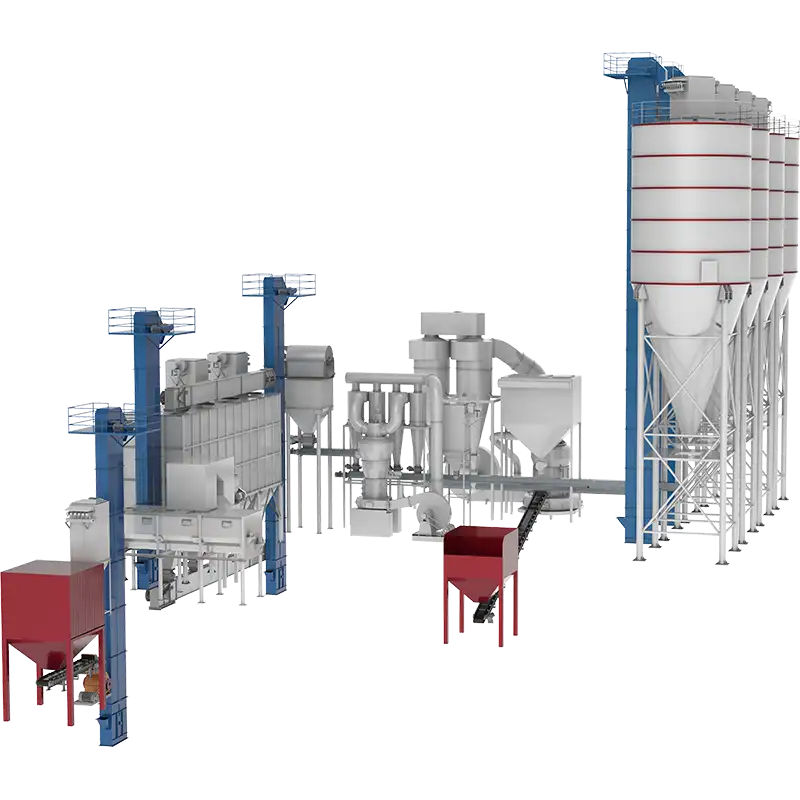

Calcium hydroxide, as an important basic chemical raw material, is widely used in various fields, including environmental protection, construction, medicine, and food. With market demands for product quality and production efficiency continuously increasing, selecting advanced production lines has become crucial for companies to enhance their competitiveness. Recently, a high-efficiency calcium hydroxide production line in the industry has attracted widespread attention for its innovative technology and significant advantages.

I. Core Advantages and Innovations of the Calcium Hydroxide Production Line

- Intelligent Control System

The production line is equipped with a DCS system, offering one-touch or zoned start and stop functions, supporting fault warnings and coordinated shutdowns, and displaying maintenance information and production capacity data. The intuitive, logically designed, and quick-to-use user interface greatly facilitates production management.

- High-efficiency Digestion System

Utilizing pulsed water mist three-stage dust removal technology, it recovers heat and promotes digestion and decomposition. The patented water mist dust removal design creates a water film on the inner wall of the pipe, effectively preventing sticking. Real-time weighing and metered water distribution ensure uniform digestion. The pre-mixing speed is adjustable, the depth of the trough material layer is controllable, and the thermal insulation performance is excellent.

- Fine Powder Selection System

Small footprint and low capital investment; capable of customizing low-density powders; high airflow and excellent centrifugal collection, resulting in significant separation and collection efficiency. Fineness can reach up to 98% at 500 mesh, resulting in high powder purity and low impurity content, meeting a wide range of fineness requirements.

- Integrated Grinding and Separation Design

Proven technology, high production capacity, adjustable fineness and purity; low powder content in slag discharge, and integrated dust removal technology ensure environmental compliance and stable production.

Innovative Highlights

Optimized Structure: The equipment features built-in insulation and temperature sensors, reducing heat dissipation points and ensuring precise temperature control, making it suitable for producing high-quality products.

Two-stage Digestion Design: Requires only three variable-speed drive units, resulting in low energy consumption and a capacity equivalent to a Class 7 digester on the market.

Flexible Customization: Production capacity and volume can be designed to meet your needs.

Reduced Costs: Reduces one-time investment in steel structure, foundation, and factory building by nearly one million yuan.

II. Application Cases

Client Background: A large environmental protection company engaged in flue gas desulfurization and wastewater treatment had extremely high requirements for the purity and fineness of its calcium hydroxide products.

Solution: The company introduced a high-purity, high-fineness calcium hydroxide production line, utilizing advanced processes and equipment to comprehensively improve product quality.

Results: Product purity was significantly improved, production efficiency was significantly increased, wastewater discharge met standards, environmental indicators were met, and the company’s core competitiveness was further enhanced.

III. Product Parameters

| Item | Parameter |

|---|---|

| Equipment Model | CRW |

| Production Capacity | 8 ~ 50 t/h |

| Finished Product Fineness | 200 ~ 800 mesh |

| Specific Surface Area | 40 m²/g |

| Installed Power | 322 kW |

IV. Market Outlook

Environmental Policy Drive

With increasingly stringent environmental policies, demand for calcium hydroxide applications in desulfurization, wastewater treatment, and other fields continues to grow. High-efficiency and environmentally friendly production lines will gain an advantage in the market.

Increasing Demand in High-End Markets

Demand for high-quality calcium hydroxide continues to increase across various industries. The production line can provide high-purity, uniformly fine products to meet the needs of high-end markets such as pharmaceuticals, food, and fine chemicals.

Resource Recycling

The production line supports wastewater treatment and recycling, aligning with the concept of green and sustainable development. It will play a greater role in resource recycling in the future.

Conclusion

Technological upgrades in calcium hydroxide production lines not only address the pain points of traditional processes but also, with their intelligent, energy-saving, and environmentally friendly advantages, provide a solid foundation for companies to expand into high-end markets and address environmental regulations. As the industry continues to develop, advanced calcium hydroxide production lines are poised to play a vital role in the transformation and upgrading of more companies.