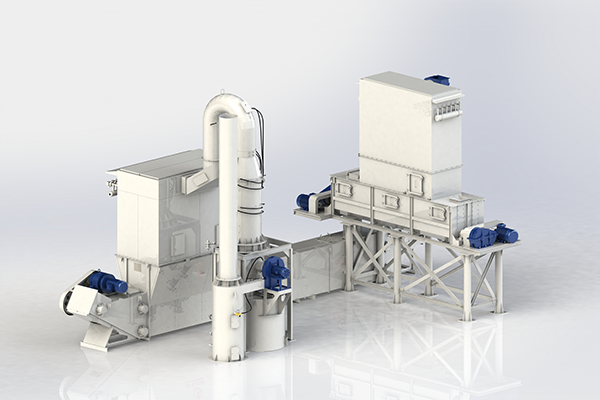

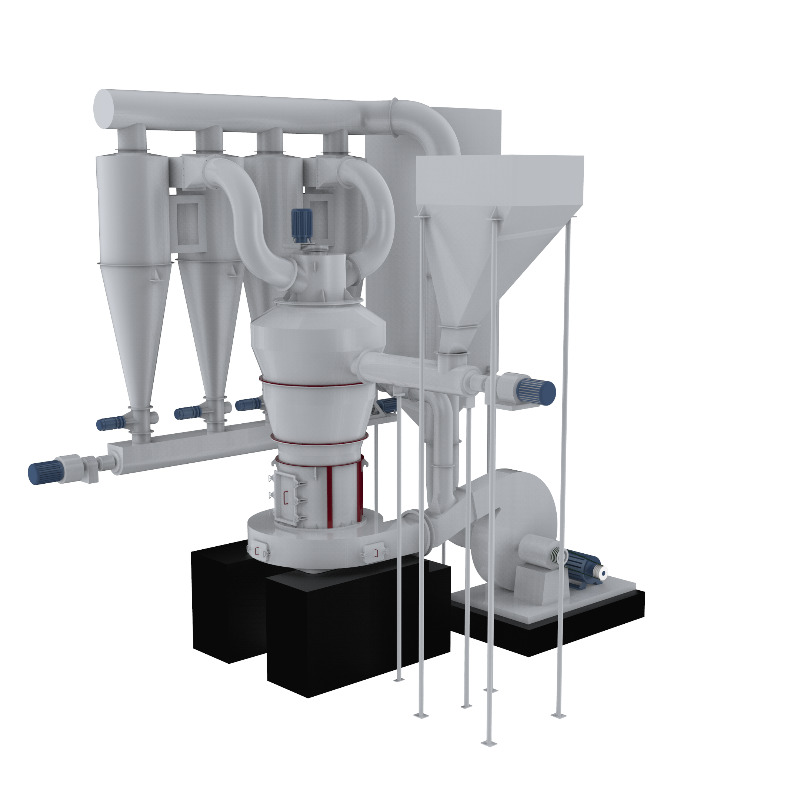

Calcium hydroxide production line

CRW series calcium hydroxide production line is a finished powder lime deep processing technology equipment developed and designed based on the characteristics and uses of calcium hydroxide powder and lime powder.

It is the result of Cronus’s many years of experience in the industry and has a variety of categories. It can produce high-purity, high-fineness, high-activity, high-specific surface area, and high-porosity calcium hydroxide, with a production capacity of 8~50t/h, a finished product fineness of 200~800 mesh, a specific surface area (BET) of 17~23m²/g (without additives), ≥40m²/g (with additives), which can meet the personalized needs of different customers.

Demand and evaluation of high specific surface area calcium hydroxide production line

Different application scenarios have different requirements for the quality, purity, particle size distribution and other aspects of high specific surface area calcium hydroxide. Before purchasing a production line, companies need to conduct a basic demand assessment.

Specific surface area requirements: The calcium hydroxide required in environmental protection desulfurization, agricultural chemistry and other fields has a large specific surface area. Therefore, the production line needs to have an efficient grinding and grading system to ensure that the product specific surface area meets the application standard.

Capacity requirements: For companies of different sizes, the daily capacity of the production line is crucial. Small and medium-sized enterprises can choose production lines with moderate output, while large companies need equipment with higher capacity to meet market demand.

Particle size control: Fineness and particle size distribution directly affect the reactivity and adsorption performance of the product. Depending on the application field, the production line needs to have precise grading control capabilities to achieve the ideal particle size range.

Advantages of CRW high specific surface area calcium hydroxide production line

As a veteran enterprise in the field of domestic powder equipment, Cronus has been deeply involved in the field of calcium hydroxide powder for many years. During this period, it has experienced a lot of visits, surveys and on-site observations. It has periodically designed, improved and practiced with users, and has a deep understanding of the physical and chemical properties of calcium hydroxide powder production. It has refined the design of process equipment according to the use of powder and equipment operating conditions, and can provide customers with effective solutions.

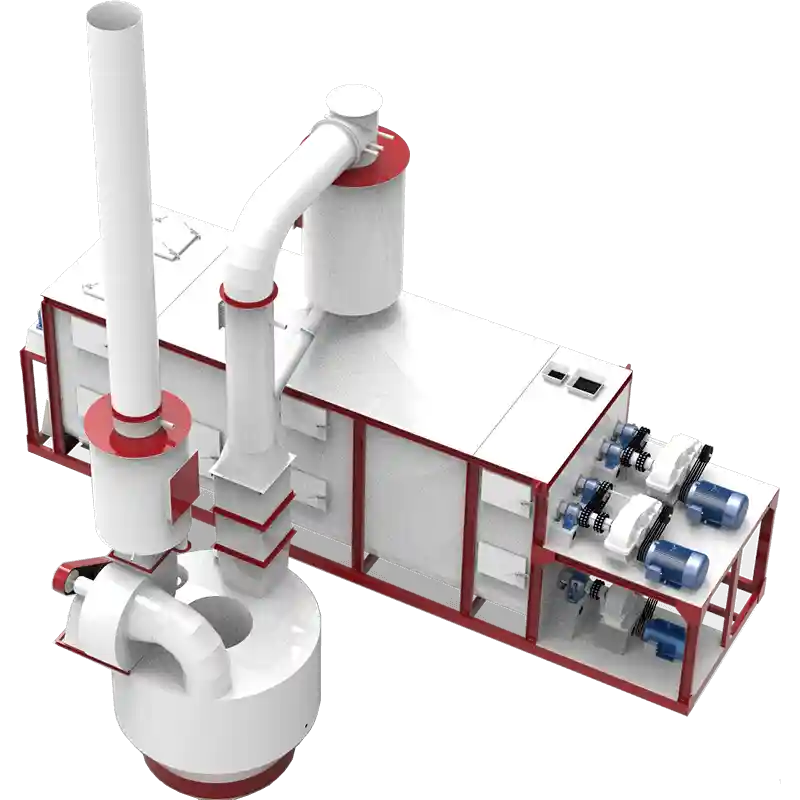

Combined module:

production capacity and equipment volume can be customized, with its own insulation layer and temperature sensing device, structural breakthrough design, few uncontrollable heat dissipation points, excellent temperature maintenance ability, suitable for high-quality and high specific surface production conditions; two-stage digestion design, low energy consumption, only three sets of variable speed drive devices, this level of volume is equivalent to the market 7-level digestion volume. Greatly reduced the investment cost of the production line’s primary steel structure/foundation/plant (less nearly 1 million).

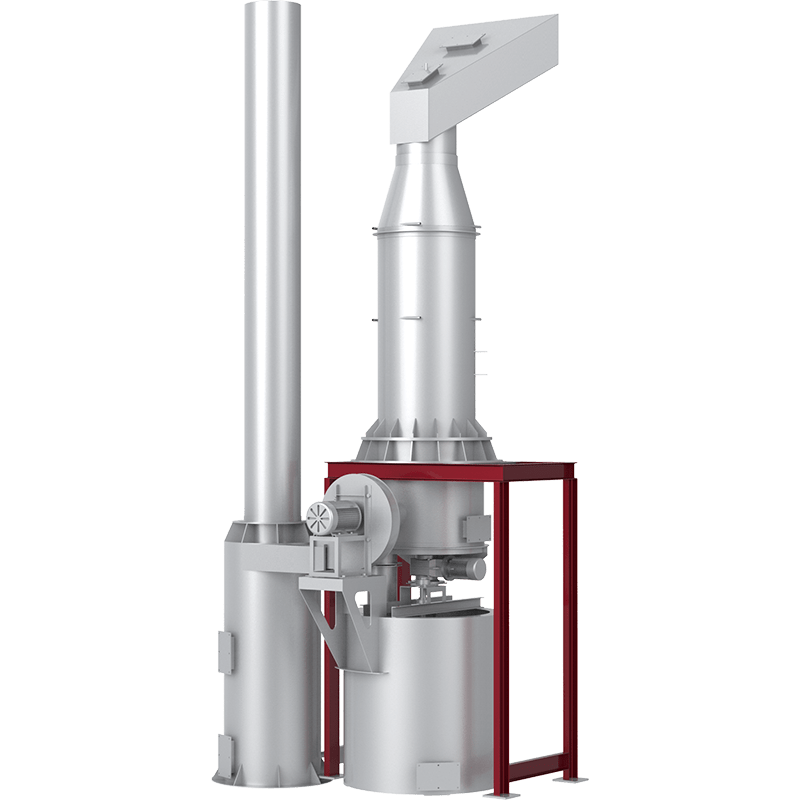

Pulse water mist digester:

pulse water mist three-time dust removal, heat recovery and utilization, promote digestion and decomposition; patented water mist dust removal, pipeline side wall water film anti-adhesion. Real-time weighing, feeding, metering and water distribution; adjustable pre-mixing speed, controllable trough material layer depth, good heat preservation and digestion-promoting effect, providing favorable conditions for high-quality or high specific surface calcium hydroxide.

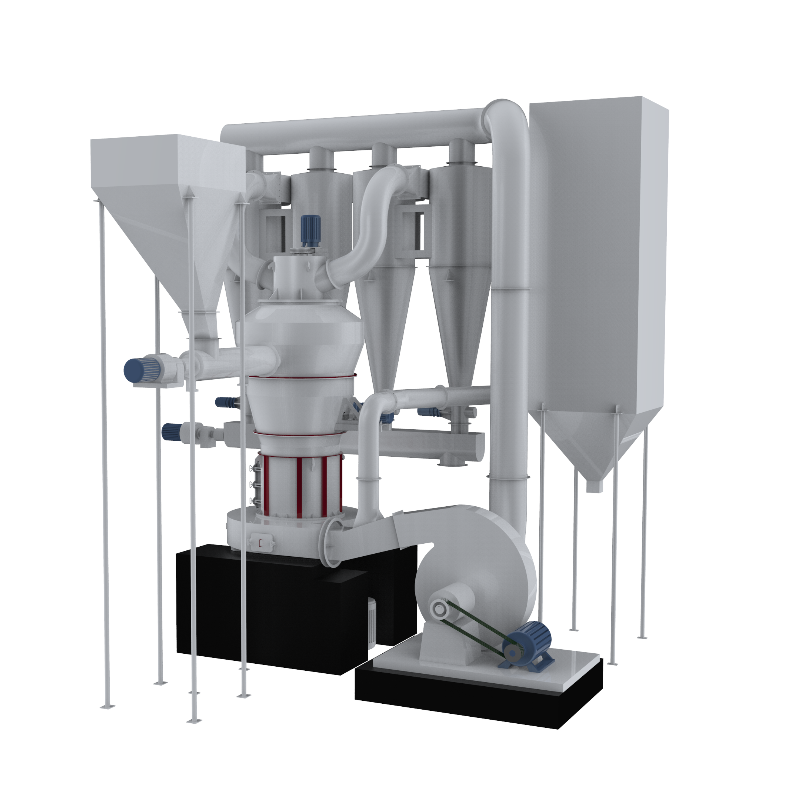

Powder selection system:

small space occupation and less infrastructure. Customized low-specific gravity powder, fast airflow speed, good centrifugal collection effect, high sorting and collection efficiency; high fineness, 500 mesh 98% pass sieve; low probability of secondary collision, low probability of impurity powder formation, small specific surface effect, and high powder purity.

Grinding machine:

mature technology, high production capacity, serialization; fineness, adjustable within the purity range; controllable slag powder content, matching process dust removal, low powder content.

Environmentally friendly and energy-saving design:

its production line equipment adopts low-energy calcination technology and high-efficiency dust removal system, which can greatly reduce dust emissions and meet environmental protection standards. Energy-saving equipment design also significantly reduces production costs.

Intelligent control system:

The production line is equipped with an automated control system, one-button or zoned start and stop, fault warning and linkage stop, maintenance information and capacity display, support monitoring and adjustment of the entire production process, improve the stability and operability of the production process, and effectively reduce labor costs and human errors.

Complete after-sales and technical support:

The company provides customers with full-process services from selection, installation and commissioning to after-sales maintenance. The technical team can respond to customer needs in a timely manner and provide training and guidance on production operations to ensure the smooth production process of customers.

Choosing a high specific surface area calcium hydroxide production line requires comprehensive consideration of technical indicators, supplier qualifications and after-sales service. Cronus has significant advantages in equipment performance, environmental protection and energy saving, intelligence and after-sales service, and can provide customers with stable and efficient production solutions. For enterprises, choosing a supplier with technical strength and high-quality services can greatly improve production efficiency and stabilize product quality.