Calcium hydroxide equipment: calcium hydroxide grinding machine

Introduction to calcium hydroxide grinding machine

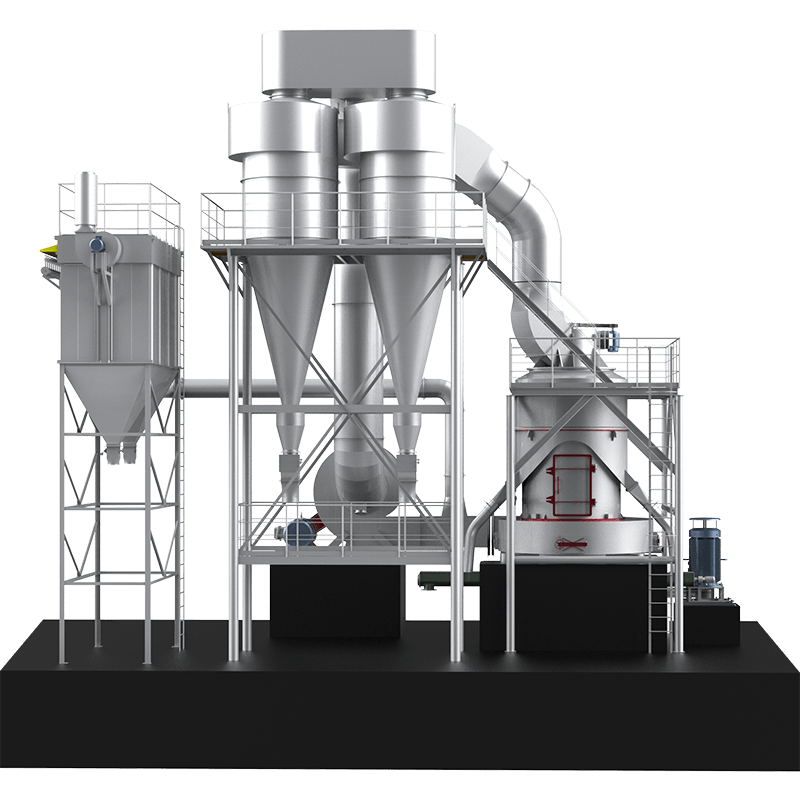

The calcium hydroxide grinding machine is composed of main machine (including reducer), classifier, disperser, blower, feeder, pipeline system, pulse collector, electric control cabinet and other parts. It is a kind of equipment that integrates screening and grinding functions. It greatly simplifies the production process and improves production efficiency. It can not only accurately complete the screening task, but also perform grinding work efficiently, playing an indispensable role in the production process of calcium hydroxide.

Application scenario: Calcium hydroxide grinding machine is widely used in grain processing, chemical industry, pharmaceutical industry and other industries.

parameter table

| Main machine maximum feed size | 20mm |

|---|---|

| Finished product particle size | 200~325 mesh (pass rate 95%) |

| Output (water content < 2%) | >13-9t/h |

| Center shaft speed | 112r/min |

| Grinding ring outer diameter | Φ1500mm |

| Grinding roller size (Ø × height) | Φ450×280mm |

*The above data is for reference only. Please refer to the actual product or product manual for specific information.

Customer site