Common Problems in Using Calcium Hydroxide Equipment

Equipment Blockage

Cause: Calcium hydroxide easily absorbs moisture and forms lumps, leading to blockages in pipes or equipment.

Solution: Clean the equipment regularly, keep it dry, and install filtration equipment if necessary.

Dust Pollution

Cause: Calcium hydroxide powder easily creates dust, which affects the environment and operator health.

Solution: Install dust removal equipment and have operators wear protective gear.

Equipment Corrosion

Cause: Calcium hydroxide is corrosive, and long-term exposure can damage the equipment.

Solution: Use corrosion-resistant materials and regularly inspect and replace damaged parts.

Unstable Product Quality

Cause: Raw material purity, equipment accuracy, or improper operation can affect product quality.

Solution: Strictly control raw material quality, regularly calibrate equipment, and standardize operating procedures.

Equipment Wear

Cause: The grinding and transportation of calcium hydroxide can cause equipment wear.

Solution: Use wear-resistant materials and regularly maintain and replace wearing parts.

High Energy Consumption

Cause: Improper equipment design or operation leads to increased energy consumption.

Solution: Optimize equipment design, improve operating procedures, and perform regular maintenance.

Through regular maintenance, optimized operation and strengthened safety management, common problems of calcium hydroxide equipment can be effectively reduced and smooth production can be ensured.

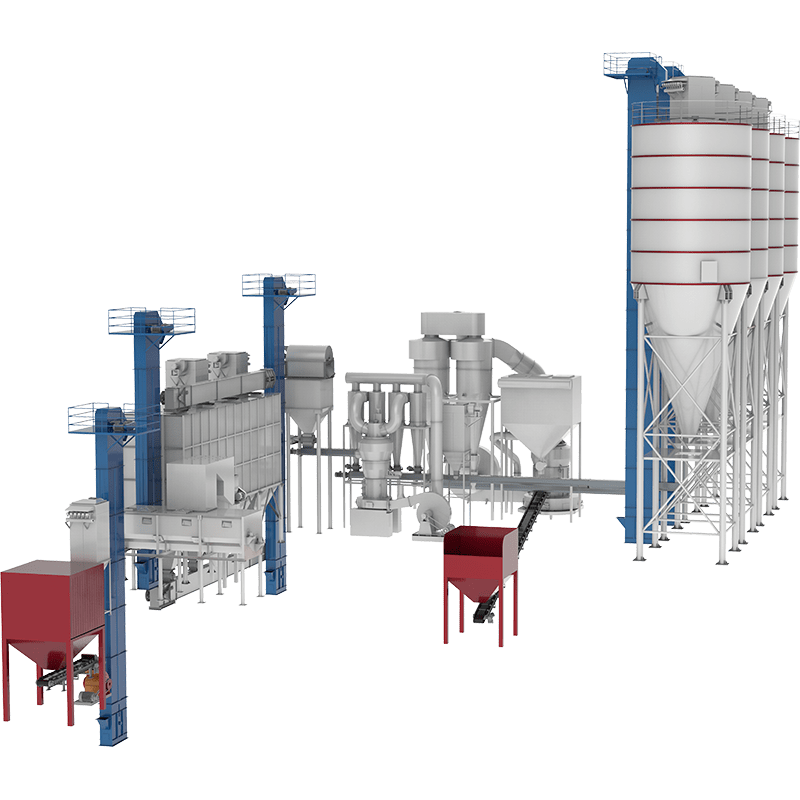

Customer Sites