Calcium Hydroxide Production: Choose the Best Classifier-Grinding Machine or Powder Classifier

In calcium hydroxide production, the choice between a grinder and a powder classifier requires comprehensive consideration of the raw material condition, product fineness requirements, and production scale. The two have significant functional differences and are applicable in different scenarios. A detailed analysis is provided below:

I. Core Functional Differences

Grinder and Classifier:

Combines grinding and classifying, directly crushing lumpy or coarse particles to the target fineness (e.g., 80-600 mesh) through extrusion and impact.

Suitable for large raw material particles that require both grinding and preliminary classification in one go, resulting in a streamlined process and space-saving operation.

Representative equipment, such as the Raymond mill, is suitable for small and medium-sized production and offers cost-effectiveness.

Powder Classifier:

Focuses on powder classification, separating the ground material by particle size using airflow or centrifugal force, removing coarse or ultrafine powders and ensuring uniform particle size.

Suitable for raw materials with a pre-defined fineness that require precise particle size control (e.g., 200-325 mesh) or for improving product purity.

Cyclone classifiers, for example, utilize high-speed airflow for efficient classification, are energy-efficient and environmentally friendly, and are suitable for high-precision requirements.

II. Applicable Scenarios and Selection Logic

Raw materials are lumpy or coarse particles:

A combined classifier and grinder is recommended: Directly crush to the target fineness, reducing equipment cascade costs. For example, a vertical mill is suitable for large-scale production and can simultaneously dry high-moisture raw materials.

Raw materials are already finely ground and require refined classification:

A classifier is recommended: Isolate to specific particle size ranges, improving product uniformity and meeting the stringent requirements of flue gas desulfurization and high-end building materials.

High-precision, large-scale production:

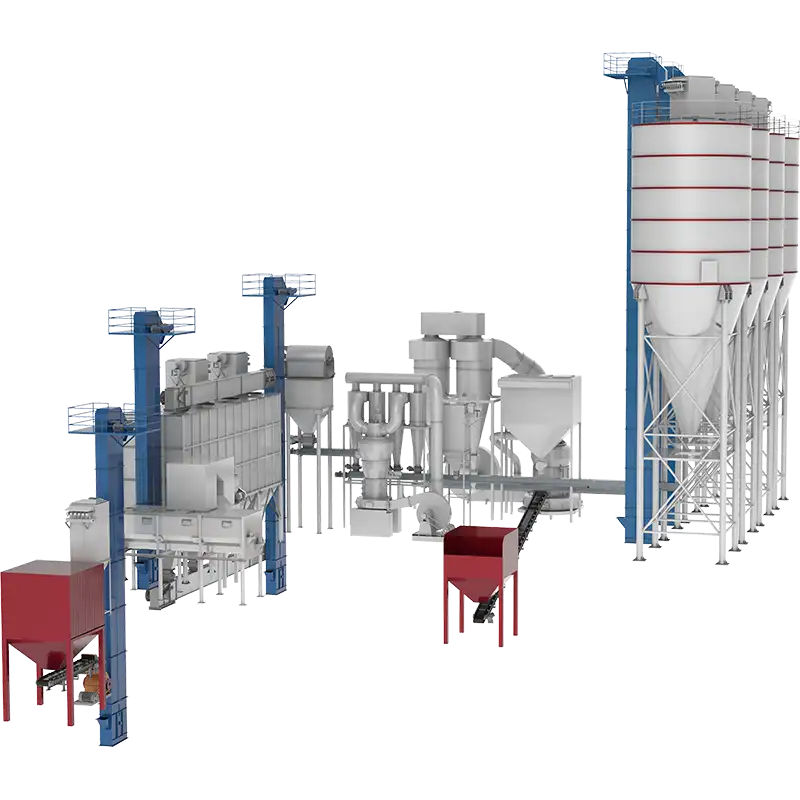

A “mill + classifier” combination system is recommended: The mill performs initial grinding, while the classifier provides precise classification, creating a closed-loop system (with coarse powder re-grinding). This ensures a concentrated and stable particle size. While the initial investment is high, the product quality and efficiency advantages are significant.

III. Key Considerations

● Raw material characteristics: Agglomerated or impure materials require pre-treatment in a mill; fine powders are more economical with a classifier.

● Production Scale: For small and medium-sized production, choose an all-in-one machine; for large-scale production, choose a combined system.

● Product Requirements: High uniformity and low impurities require classifying equipment.

Conclusion:

For coarse raw materials and small-scale production, a classifier-grinding machine is efficient and convenient. For high precision or large-scale production, a classifier combined with a grinding mill is more effective. We recommend customizing your production line based on a balance between cost and quality, tailored to your specific needs.