Analysis of the Complete Components System of Shanghai Cronus Calcium Hydroxide Production Line

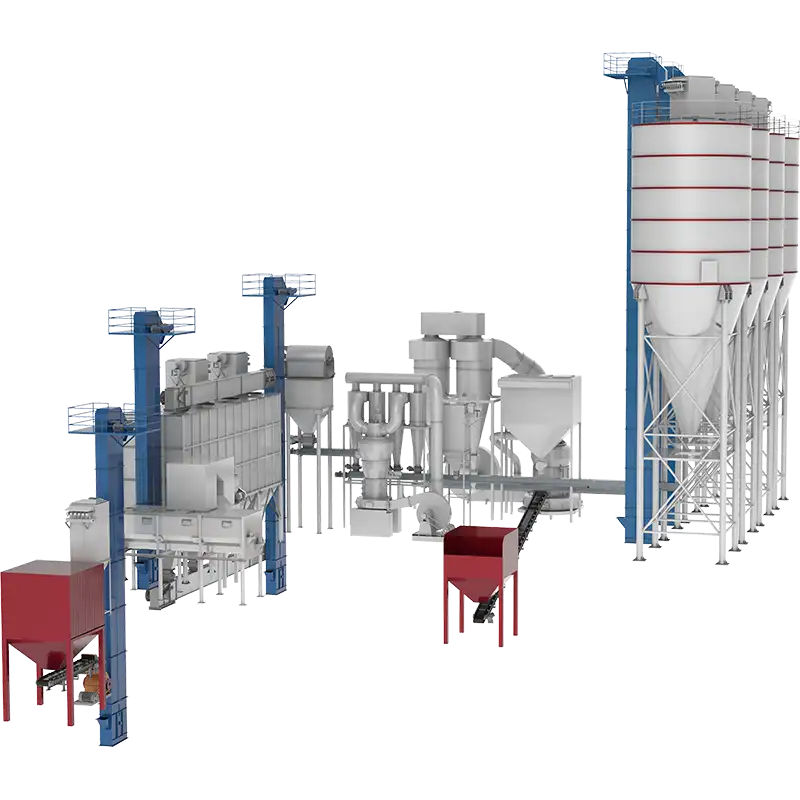

As a leading enterprise dedicated to the research and development and manufacturing of high-end powder processing equipment, Cronus has been deeply engaged in the fields of environmental protection and industrial automation. Its independently developed calcium hydroxide (slaked lime, Ca(OH)₂) production line deeply integrates international process design with sustainable innovation concepts. It is widely applied in multiple core fields such as environmental protection governance, high-end building materials, fine chemicals, and food processing.

The production line not only possesses core advantages such as high production capacity, energy conservation and consumption reduction, and environmental friendliness, but also relies on a global technology research and development system and intelligent system integration capabilities to achieve full-process automated and intelligent control from raw material pretreatment to finished product delivery. The following will systematically analyze all the key components and core functions involved in the Shanghai Cronus calcium hydroxide production line, highlighting the technical core and manufacturing strength.

I. Core Reaction System: Lime digestion (ripening) equipment

As the core link in the generation of calcium hydroxide, this system precisely regulates the hydration reaction process between quicklime (CaO) and water, ensuring the purity and activity of the calcium hydroxide product. It is a key unit that determines the quality of the product.

Lime digester (ripening machine)

Cronus customizes the configuration of digestion equipment according to different production capacity requirements to ensure reaction efficiency and product consistency

Horizontal digester: Suitable for large-scale continuous production scenarios, with a production capacity ranging from 1 to 30 tons per hour. It features thorough reaction, high thermal efficiency, and stable operation, and can meet the mass production demands of large-scale industrial projects.

- Vertical digester: It adopts a compact structure design, significantly reducing the floor space. It is equipped with a precise temperature control system and is suitable for small and medium-sized production lines and project scenarios with limited space.

- Double-shaft stirring digester: Equipped with a self-developed double-screw stirring structure, it achieves uniform mixing of materials and water, with a digestion rate of ≥95%, effectively reducing unreacted residues and improving the utilization rate of raw materials.

Core components

- Corrosion-resistant stainless steel reaction vessel body: Made of high-quality stainless steel, it features excellent high-temperature resistance and corrosion resistance, making it suitable for high-temperature environments and alkaline media in digestion reactions.

- Intelligent variable frequency speed control drive system: It can precisely adjust the speed according to the material characteristics and reaction progress, achieving flexible production and reducing energy consumption.

- High-strength wear-resistant stirring blades: Forged from special alloy wear-resistant materials, they extend service life and ensure uniform stirring.

High-precision temperature and pressure sensors: Real-time collection of temperature and pressure data inside the reaction chamber, providing precise basis for system regulation.

- Intelligent automatic water addition control system: Precisely regulates the water-calcium ratio based on weighing feedback data to ensure thorough reaction and stable product quality.

- Feeding system

- Vibrating feeder: Equipped with adjustable amplitude function, it ensures uniform and stable supply of quicklime block materials, effectively avoiding feeding blockage and precisely matching the feeding volume with the processing capacity of the digester.

- Sealed screw conveyor: It adopts a fully sealed structure design to smoothly convey block or powdered quicklime to the digester, effectively preventing dust from overflowing from the source and ensuring a clean production environment.

- Intelligent weighing sensor and PLC control module: Achieve real-time measurement and closed-loop regulation of quicklime feed volume, accurately complete the batching process, and lay the foundation for automated production.

Ii. Material Conveying and Handling System

This system is responsible for the efficient and clean transmission of materials between various processes. Through modular configuration, it ADAPTS to different conveying paths and material forms, ensuring the continuity and stability of the production process.

- Sealed screw conveyor: Focusing on the horizontal transportation of powder materials, its fully sealed structure design effectively prevents dust from spilling out, making it suitable for short-distance material transfer.

- High-efficiency bucket elevator: It adopts anti-clogging and anti-deviation design to vertically lift materials to the high-level silo, featuring large conveying capacity and low energy consumption.

- Intelligent pneumatic conveying system: It can be flexibly configured with positive pressure or negative pressure conveying modes according to the conveying distance and multi-point material distribution requirements, suitable for long-distance and multi-point powder conveying scenarios. The conveying process is clean and residue-free.

Buffer silos and intermediate storage tanks: Equipped with intelligent level gauges, they can monitor the material stock in real time, achieving a balance between production buffering and continuous feeding, and avoiding process interruptions.

Iii. Dust Removal and Environmental Protection Systems

Shanghai Cronus adheres to the concept of sustainable development, builds a full-process environmental governance system, ensures that the production process strictly complies with national environmental protection standards, and achieves the goal of green manufacturing.

Pulse bag dust collector

Precisely positioned at core dust-generating points such as digestion, grinding, and packaging, it achieves efficient collection and purification of dust

Core components

High-temperature resistant coated filter bags: Made of high-end coated filter materials, they feature excellent filtration accuracy and wear and high-temperature resistance. They can effectively intercept fine powder particles, with a dust removal efficiency of up to ≤5mg/m³.

- Intelligent pulse jet cleaning system: Automatically initiates the cleaning program based on differential pressure feedback to ensure the air permeability of the filter bags and maintain stable dust removal efficiency.

- Differential pressure sensor and automatic control module: Real-time monitoring of filter bag resistance changes, achieving intelligent regulation of the ash cleaning process and reducing operation and maintenance costs.

- Desulfurization and denitrification supporting equipment (Special configuration for flue gas treatment)

For flue gas treatment scenarios, dedicated reaction towers, precise spray systems and other equipment are provided to fully leverage the desulfurizer properties of calcium hydroxide, achieving efficient removal of sulfides and nitrogen oxides in flue gas, and helping industrial enterprises achieve their environmental protection and emission reduction goals.

Iv. Finished Product Handling and Packaging System

Achieve precise grading, clean packaging and safe storage of calcium hydroxide products to ensure stable product quality and efficient outbound operations.

- High-precision vibrating screen: Equipped with multi-layer grading screens, the screening accuracy can be flexibly adjusted according to customer needs to achieve precise grading of finished product particle size and ensure product consistency.

- Intelligent automatic packaging machine: It offers two core configurations: 25kg/ bag small bag packaging and 1-ton/bag ton bag packaging, suitable for different transportation and usage scenarios. The equipment integrates high-precision load cells and an automatic sealing device to ensure accurate measurement and tight sealing. An optional robot palletizing system can be equipped to achieve fully automatic palletizing and loading of packaged finished products