It’s that easy! From stone to magic powder: How to make slaked lime

In the industrial and construction sectors, slaked lime is a fundamental yet indispensable material. Many users search for “how is slaked lime made” to understand its production process. This article, focusing on this keyword and using Cronus lime production line equipment, systematically explains the slaked lime production process and related equipment configuration.

I. What is slaked lime? Introduction to slaked lime

Slaked lime, also known as calcium hydroxide (Ca(OH)₂), is formed by the reaction of quicklime (CaO) and water. It is a white powder with strong alkalinity and is widely used in various applications, including building plastering, water treatment, and agricultural soil improvement.

The basic reaction equation is as follows:

CaO + H₂O → Ca(OH)₂ + heat

II. How is slaked lime made?

Raw material selection: limestone (CaCO₃)

Selecting high-purity limestone is a prerequisite for producing high-quality slaked lime. Guilin has abundant limestone resources and is a natural source of this raw material.

Quicklime Slaking: How is it made into slaked lime?

This is the core step in answering the question of how slaked lime is made.

Calcinated quicklime is mixed with water and passed through a Cronus intelligent slaking system (such as a slaking tank or continuous lime slaking machine), causing an exothermic reaction to produce slaked lime powder:

CaO + H₂O → Ca(OH)₂

Lime Slaking Machine

Features: Full reaction, automatic temperature control, and prevention of overheating and agglomeration

Automated Control

The equipment automatically controls the amount of water added, stirring speed, and reaction temperature to ensure uniform lime slaking and reduce manual errors.

Improves efficiency and output

Compared to traditional manual digestion, it offers faster reaction times and more stable slurry quality, making it suitable for continuous production.

Excellent Safety

The reaction releases significant heat. This equipment operates in a closed manner and controls the temperature rise, minimizing the risk of splash burns.

Reduces maintenance and clogging.

Internal stirring and anti-caking design prevent material accumulation in the reaction tank, extending equipment life.

Reduces operating costs.

High lime utilization reduces waste and reduces energy consumption in subsequent filtration and transportation of the slurry.

III. Advantages of Cronus Lime Production Lines

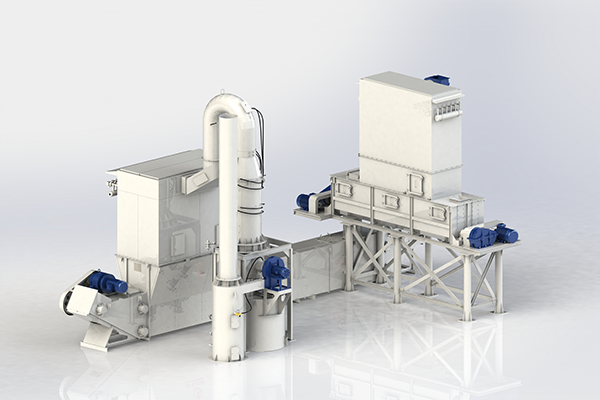

Cronus provides customers with a one-stop hydrated lime production solution, including:

✅ Automated lime kiln design

✅ Complete quicklime digestion line equipment

✅ Hydrated lime powder preparation and packaging system

✅ Environmentally friendly dust removal system

✅ Full process control system (PLC)

With extensive industry experience, Cronus has developed comprehensive solutions for lime industry equipment manufacturing, suitable for projects with annual production capacities ranging from 10,000 to 300,000 tons.

IV. Key Applications of Hydrated Lime

Construction (mortar, lime mortar)

Municipal and industrial water treatment (pH adjustment)

Agricultural soil improvement

Neutralization and desulfurization in the chemical and metallurgical industries

Food and pharmaceutical industries (high-purity grades)

V. Summary:

How is slaked lime made? Choose Cronus for greater efficiency.

Cronus builds an efficient, environmentally friendly, and sustainable slaked lime production line, from raw material processing and calcination to digestion and milling.

If you’re looking for a proven lime production solution or equipment supplier, Cronus is your reliable partner.