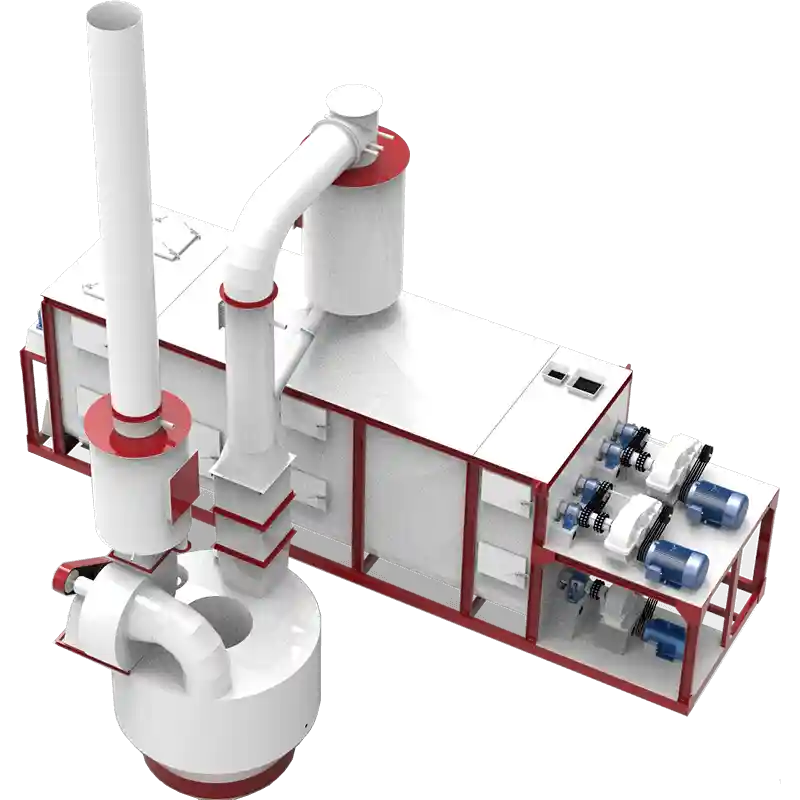

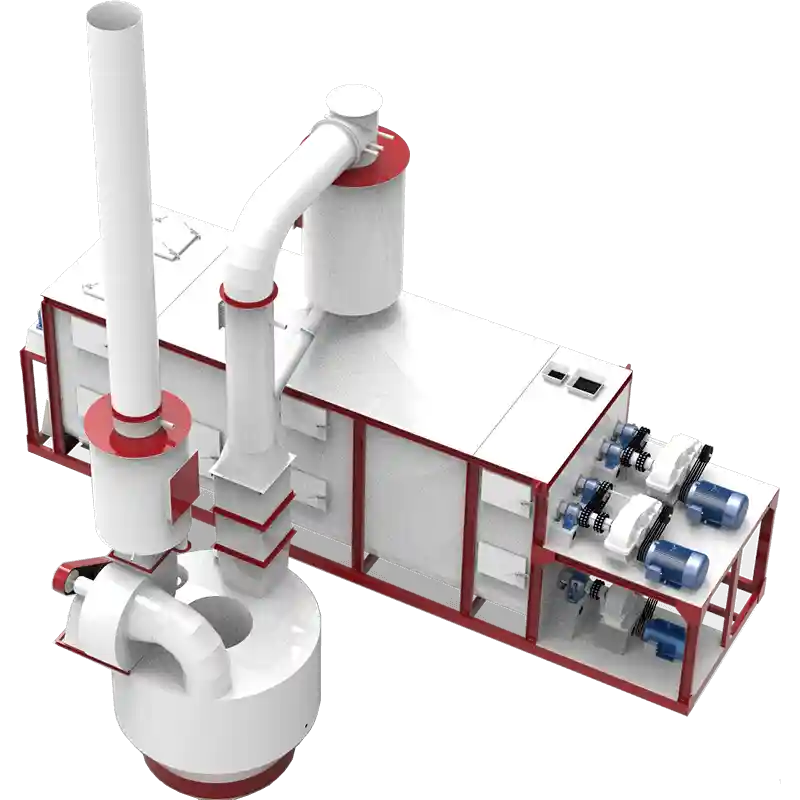

Water mist dust collector

→

During the digestion process, lime will produce a large amount of hot water vapor, and carry a certain amount of calcium hydroxide powder.

→

After the pulse dust collector is used for dust removal, it enters the preheated water mist dust collector for two or three times to collect the powder mist and become clean hot water vapor, which is discharged into the atmosphere through the pipeline.

→

The calcium hydroxide water collected by the preheated water mist dust collector in the water storage tank has a water temperature of 60-80 degrees Celsius.

→

A small amount of sediment is circulated by the general sewage pump into the first-level pre-digestion to promote the chemical reaction of quicklime.

This process helps to shorten the digestion time, improve the quality of calcium hydroxide and discharge no sewage.

Capacity: >15~18t/h

In the process of converting calcium oxide (CaO) into calcium hydroxide (Ca(OH)₂) by adding natural water (H₂O), a large amount of hot steam is generated, and a certain amount of calcium hydroxide dust is entrained in the gas.

If it is naturally discharged into the air, it will inevitably cause white pollution, which will seriously affect the surrounding environment of the factory (factory production area).

The use of water mist dust collector will completely solve the source of white pollution and beautify the surrounding environment of the factory.

Calcium hydroxide equipment: parameter comparison table of water mist dust collector

| Parameter | Specification |

|---|---|

| Maximum Feed Size | ≤10mm |

| Processing Capacity | >15~18t/h (varies by model, region, and ore raw materials) |

| Dust Removal Method | Pulse + Preheated Water Mist Dust Removal |

| Feed Material | Digested Calcium Hydroxide |

| Finished Product Particle Size | 200~400 mesh (95% pass rate) |

| Output* | >9~13t/h (based on calcium hydroxide processing, water content <6%; capacity 18-20 tons) |

| Notes | *Above data is for reference only. Refer to actual product or manual for details. |

Calcium Hydroxide Equipment: Functional Characteristics of Water Mist Dust Collector

In the chemical reaction: CaO + H₂O → Ca(OH)₂,

the process generates large amounts of hot steam

carrying calcium hydroxide powder.

Natural discharge would cause white pollution,

significantly impacting the factory environment.

Our system features:

- 1st stage: Pulse dust collector for initial filtration

- 2nd-3rd stage: Preheated water mist dust collectors

- Final output: Clean hot steam for safe atmospheric discharge

Collected calcium hydroxide water maintains optimal temperature of

60-80°C in storage tank.

✓

Closed-loop System Advantage:

Sediment recirculation via sewage pump enhances quicklime reaction, achieving:

- 30-50% faster digestion time

- Higher purity calcium hydroxide

- Zero wastewater discharge

Calcium hydroxide equipment: Product features of water mist dust collector

The preheating calcium hydroxide water mist dust collector is a patented product of Cronus Machinery Company. It features:

- Compact structure with small footprint

- Excellent digestion-promoting effect

- Superior dust control capabilities

Comparison with conventional pulse dust collectors:

- Reduced bag requirements (no need for simultaneous dust removal, alkali resistance, waterproof, temperature/pressure resistance, and non-stick properties)

- Maintenance can be performed during scheduled downtime rather than requiring immediate shutdown

- Minimized pipeline length to prevent calcium hydroxide buildup

Unique design features:

- Water curtain protection on side walls

- Alternating circulating/clean water washing system

- Effective spray, dust, and temperature collection

- Built-in de-whitening function

✓

Three-Stage Dust Removal Process:

- 1st stage: Single pulse dust removal

- 2nd-3rd stage: Water mist comprehensive dust removal

- Obvious dust removal and waste heat collection effects that meet emission standards