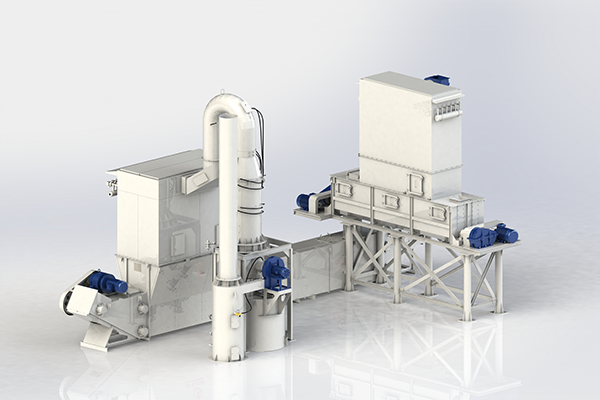

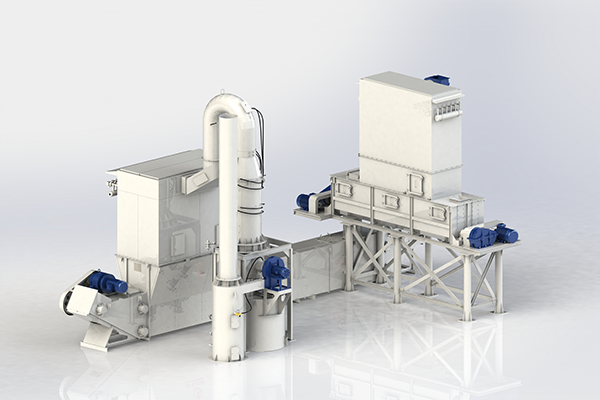

Calcium hydroxide equipment: Introduction to Lime Digester equipment

Technical Specifications

Production Capacity

15~50t/h

Application Scenarios

- Construction Industry: Produces slaked lime for construction, masonry, plastering, etc.

- Chemical Industry: Used to produce calcium hydroxide and other chemical products.

- Environmental Protection: For wastewater treatment and flue gas desulfurization projects.

- Metallurgical Industry: Serves as auxiliary materials in the smelting process.

Calcium hydroxide equipment: product features of lime digester

Application Scenarios

Construction Industry

Produces slaked lime for construction, masonry, plastering, etc.

Chemical Industry

Used to produce calcium hydroxide and other chemical products.

Environmental Protection

Used for environmental protection projects such as wastewater treatment and flue gas desulfurization.

Metallurgical Industry

Used as auxiliary materials in the smelting process.

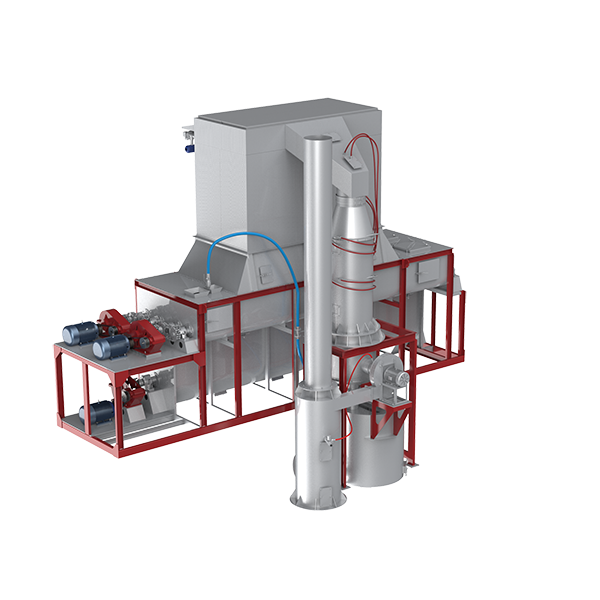

Lime Digestion Process

Raw Material Preparation

After sieving, calcium oxide (quicklime block) is crushed and lifted to the raw material warehouse (lime storage warehouse) for standby.

Controlled Feeding

When digestion begins, calcium oxide (20~40mm block material) is quantitatively and uniformly fed into the lime digestion box through a vibrating feeder with adjustable speed.

Hydration Reaction

Natural water (H₂O) is added, and the calcium oxide absorbs water for 5~8 seconds, undergoing a chemical reaction that converts it to calcium hydroxide (Ca(OH)₂), producing large amounts of hot steam.

Steam Management

The hot steam, carrying some calcium hydroxide powder, is discharged through pipelines under fan action.

Dust Filtration

Spray nozzles create a water curtain wall that filters dust from the hot steam before it’s discharged into the atmosphere.