Calcium carbonate processing technology

Calcium carbonate is an inorganic compound and the main component of limestone (referred to as limestone) and calcite. Calcium carbonate is divided into two categories: heavy calcium carbonate and light calcium carbonate.

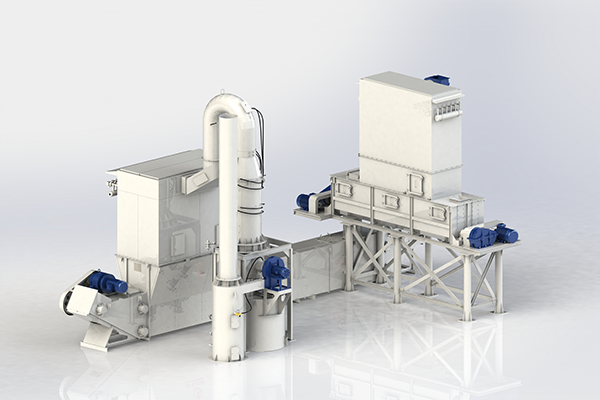

As a manufacturer of calcium carbonate production equipment, Cronus’s CRRM series Raymond mills and vertical mills; CRLMS series ultrafine vertical mills; CRGM series roller mills have been widely used in the production and processing of calcium carbonate. Today, Cronus will introduce you to the production technology and equipment of calcium carbonate processing.

Heavy calcium carbonate processing and production technology

At present, there are two main processes for industrial production of heavy calcium carbonate, one is dry process; the other is wet process. The products produced by dry process can be widely used in rubber, plastic, coating and other industries. The production of wet process is used in the papermaking industry, and the general products are sold to paper mills in the form of pulp products.

Dry process production process:

Raw materials → remove gangue → jaw crusher → impact hammer crusher → Raymond mill/ultrafine vertical mill → classification system → packaging → product.

First, select calcite, limestone, chalk, shells, etc. shipped from the quarry to remove gangue; then use the crusher to coarsely crush the limestone, and then use Raymond (swing) mill to crush to obtain fine calcite powder, and finally use the classifier to classify the ground powder, and the powder that meets the particle size requirements is packaged as a product and stored, otherwise it is returned to the mill for re-grinding.

Wet production process

The wet process is mainly used to produce ultrafine heavy calcium carbonate, especially for the papermaking industry. Its process includes the following steps:

Raw material preparation:

The fine powder produced by the dry process is made into a suspension and a dispersant is added to prevent particle agglomeration.

Wet grinding:

The suspension is sent to a wet stirred mill or a flaking machine for further crushing, and the particle size uniformity is improved through multi-stage circulation or intermittent grinding.

Classification and dehydration:

The ground material is classified by a wet classifier, and the qualified ultrafine powder is dehydrated and dried to obtain the final product.

Activation treatment:

Some wet products need to undergo surface modification to improve dispersibility and application performance.

Packaging:

The final product is bagged and sold to paper mills or other industries.

The main characteristics of the wet process are finer product particle size (usually less than 3μm) and higher quality, but its equipment requirements are high, investment is large, and energy consumption is high. In addition, the wet process can produce pulp, paste or powder products to meet the needs of different industries.

Light calcium carbonate processing and production technology

Light calcium carbonate preparation process: crush the limestone raw material into a certain size, calcine it in a lime kiln to produce quicklime (Ca0) and flue gas (kiln gas containing carbon dioxide), put the quicklime into a continuous digester and add water to digest it to obtain Ca (OH)2 emulsion, filter and refine it to obtain Ca (OH)2 refined emulsion, send it to the carbonization kettle/carbonization tower, pass refined kiln gas containing carbon dioxide to carry out carbonization synthesis reaction, and add appropriate amount of additives to react under certain process conditions to produce ultrafine calcium carbonate.

The ultrafine calcium carbonate slurry is sent to the coating reactor, and a quantitative coating agent is added to react under certain process conditions to obtain a surface-modified ultrafine active calcium carbonate product. The ultrafine active calcium carbonate slurry is filtered and dehydrated, and then sent to the dryer for further dehydration to achieve the dry powder with the required water content, and then crushed and packaged as a finished product.