Slaked Lime Production Line: Elevate Reliability with Dynamic Strategies for Flawless Maintenance

In the field of industrial production, slaked lime is an indispensable and important raw material, and the stable operation of its production line is directly related to product quality and production efficiency. Equipment maintenance is the core element to maintain the long-term stable operation of the slaked lime production line. So, how to determine the maintenance cycle of slaked lime production line equipment?

The relationship between equipment type and maintenance cycle

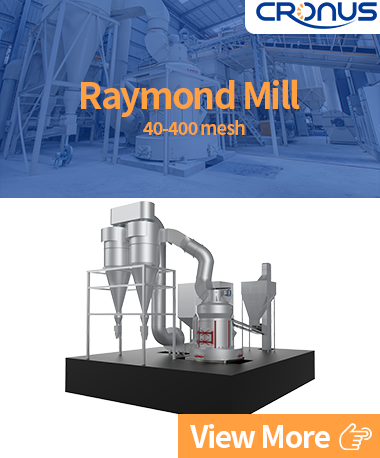

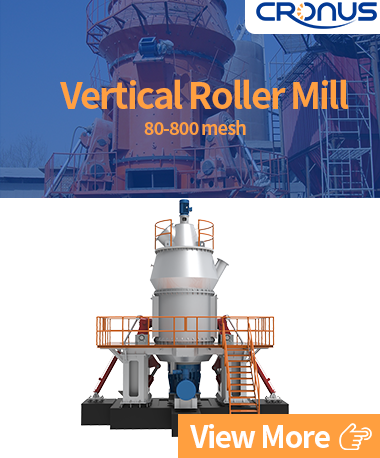

The slaked lime production line covers a wide variety of equipment, from crushers, mills, digesters, powder selectors, to dust collectors, etc. The working principles, structural characteristics and use environments of each equipment are significantly different. Because of this, the maintenance cycles of different equipment are also different.

Generally speaking, the maintenance frequency of equipment that runs at high speed and is prone to wear, such as crushers and mills, needs to be relatively increased, and the cycle is shortened accordingly; while the maintenance cycle of equipment with a relatively simple structure and a good operating environment, such as dust collectors, can be appropriately extended.

Working environment and maintenance cycle

The working environment of the slaked lime production line also has an important impact on the maintenance cycle of the equipment. For example, the equipment working in a dusty and humid environment is more susceptible to dust and moisture erosion, so its maintenance cycle should be shortened accordingly.

On the contrary, the equipment working in a dry and clean environment can have its maintenance cycle appropriately extended. In addition, the maintenance cycle of the equipment should also take into account the running time of the production line. The maintenance cycle of equipment that runs continuously for a long time should be relatively short due to the higher degree of wear and fatigue.

Specific content and implementation points of maintenance

The maintenance system of slaked lime production line equipment includes daily inspection, regular maintenance, repair and replacement, etc. Daily inspection focuses on the equipment’s operating status, lubrication status, and tightness of fasteners, so as to detect and deal with potential hidden dangers in a timely manner; regular maintenance maintains the good performance of the equipment through operations such as cleaning, lubrication, tightening and adjustment; repair and replacement promptly repairs or replaces damaged parts in response to equipment failure or damage. The implementation cycle of these maintenance measures needs to be flexibly determined based on the actual condition of the equipment and the operating environment.

Suggestions and precautions for maintenance cycle management

For the management of the maintenance cycle of slaked lime production line equipment, the following suggestions and precautions are proposed:

Improve system construction: Enterprises should build a complete equipment maintenance system, clarify the maintenance cycle, specific content and responsible parties of various types of equipment, and ensure that maintenance work can be effectively implemented.

Strengthen employee training: By improving employees’ cognitive level and operating skills of equipment maintenance, standardize equipment operation procedures, and reduce equipment failures caused by human factors.

Strengthen inspection and evaluation: Regularly inspect and evaluate the equipment operation status and maintenance effects, timely discover and solve potential problems, and ensure stable operation of equipment.

Scientifically plan production: When formulating production plans, fully consider the equipment maintenance needs, reasonably arrange equipment operation and downtime, and avoid excessive operation of equipment to cause losses.

The maintenance cycle of slaked lime production line equipment is affected by factors such as equipment type, environment, and operating conditions. Enterprises need to make comprehensive judgments and perform precise maintenance to ensure stable operation of the equipment. If you need a slaked lime production line, please contact cronus.