🔥Lime Slaker Operation🔥: greatly improve your production efficiency!!!!

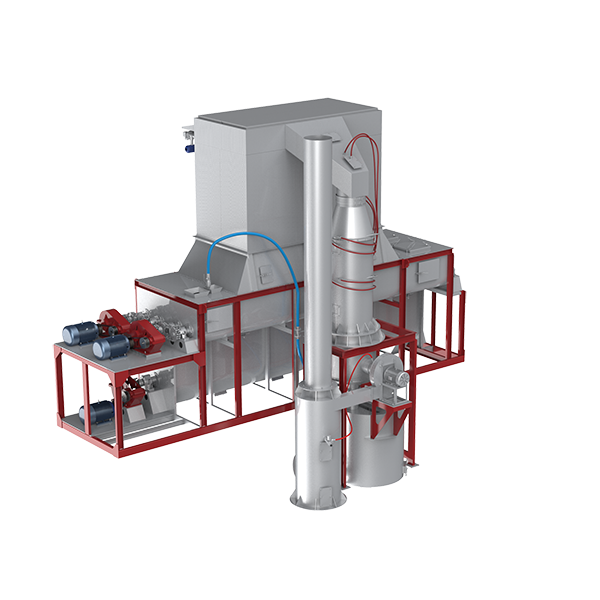

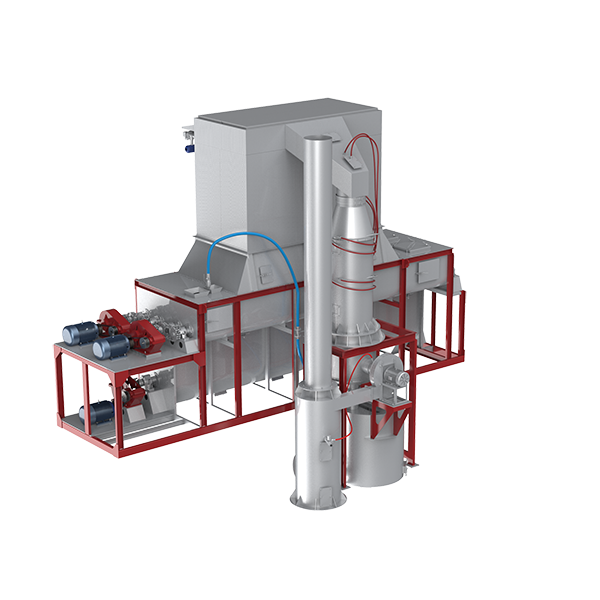

The lime digestion system is a key equipment system used in industrial production to convert quicklime (CaO) into slaked lime (Ca(OH)₂). The system achieves efficient and stable digestion operations by precisely controlling the reaction process of lime and water, and is widely used in environmental protection, chemical industry, building materials and other fields.

Important role of lime digester

Calcination of limestone

The lime digester first calcines limestone at high temperature to decompose it into quicklime and carbon dioxide (CO2). This process is usually carried out in a calcining furnace, and the limestone decomposes at high temperature: CaCO3 → CaO + CO2↑. The quicklime is then transported to the digester.

Digestion of quicklime

In the digester, quicklime reacts with water to produce calcium hydroxide and heat. This process is called digestion reaction, and the reaction equation is: CaO + H2O → Ca(OH)2 + heat. The digestion reaction is an exothermic reaction that releases a lot of heat, so effective heat dissipation measures are needed to control the reaction temperature to ensure the quality of calcium hydroxide.

Quality control

By controlling the temperature, time and amount of water added during the digestion process, the particle size, purity and activity of calcium hydroxide can be precisely controlled. These parameters are crucial for the application areas of calcium hydroxide, such as papermaking, water treatment, construction and agriculture.

Energy recovery

The heat released during the digestion process can be recycled, for example, for heating other production processes or for drying calcium hydroxide, thereby improving the energy efficiency of the entire production line.

Environmental protection

The design of lime digesters usually includes an exhaust gas treatment system to reduce dust and harmful gas emissions generated during the production process, in line with environmental protection requirements.

Continuous production

Modern lime digesters are usually designed for continuous operation to ensure stable operation of the production line and continuous supply of calcium hydroxide.

Lime Slaker Operation

Lime Slaker Operation is when the new lime digester is started, the slag elevator is started first to ensure that the waste slag is discharged in time, and then the pulse dust collector is started to collect the initial dust. Then the plug valve on the top of the preparation warehouse is opened to allow the lime raw materials to flow to the cylindrical screen through the conveying auger on the top of the preparation warehouse. After the large particles of impurities are removed by the cylindrical screen, they are lifted to the homogenizer by the bucket lift. During this period, the pulse dust collector is started again to collect and transport the dust.

Then start homogenizers 2 and 1 to homogenize the raw materials, and then start pulverizers 3, 2, and 1 in turn to refine the raw materials. At the same time, start the pulse dust collector for the third time to collect the pulverized dust. Then start the pre-mixer to make the lime and water react initially, and feed the material to the digester at a uniform speed through the feeding belt. Finally, start the water pump to provide stable water supply for the digestion reaction. All links work closely together to ensure the smooth start-up and operation of the digester.The above is the process of Lime Slaker Operation.

Core parametersinding

| Parameter | Specification |

|---|---|

| Grinding Fineness | Superfine Grinding |

| Energy Consumption | Refer to Manual |

| Production Capacity | 10-40 t/h |

| Installed Power (kW) | 105/125/202 |

| Product Fineness | 80-325 mesh |

| Max. Feed Size (mm) | ≤35mm |

| Working Principle | Roller-Compression Grinding |

Our services:

✔ Professional solution design ✔ Customized equipment production ✔ Installation and commissioning ✔ Operation training

Cronus technical team provides you with 24-hour support!