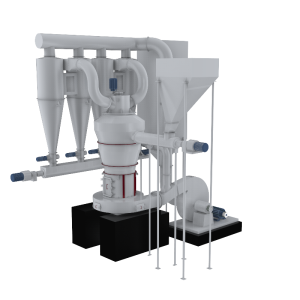

Installation Tips for a Calcium Hydroxide Plant’s Ash Calcium Machine

The entire grinding process of the ash calcium machine is manually controlled. Material is fed manually and by screw conveyor. After entering the hopper, the material is drawn into the grinding chamber. As the main shaft rotates at high speed, the material is broken down by the plates on the shaft’s plate bracket. The powder that reaches the required fineness is drawn into the air chamber and sent through a pipe to the powder collector as the finished product. The machine runs for approximately 40 minutes during the grinding process. Deslagging can be completed by depressing the slag plate for a few seconds.

The fineness of the ash calcium machine is adjusted by opening the machine’s top cover and moving the adjustment bracket. Adjusting the powder toward the feed inlet results in a coarser powder, while adjusting the powder toward the feed inlet results in a finer powder. This equipment replaces traditional, outdated processes such as ball milling, screening, and water separation. It offers advantages such as compact size, minimal footprint, light weight, energy and labor savings, low noise, excellent dust resistance, easy operation, simplified maintenance, low price, multifunctionality, low investment, and high efficiency.

Calcium Hydroxide Grinding Machine

Calcium Hydroxide Equipment Calcium Hydroxide Machine Installation Tips:

- To prevent dust leakage caused by air leaks in the ash calcium machine’s dust removal device, the ash calcium machine must be protected from sunlight and rain during installation.

- The wiring should be prepared promptly to ensure that technicians are not delayed in their installation. The main wiring should be installed first.

- During installation, a lifting device with a capacity of up to 2 tons is required to ensure adequate installation and maintenance.

- The ash calcium machine foundation should be constructed with high-grade cement and pre-buried with conduit and cable trenches. The cement foundation must be maintained for 15 days after pouring. The plant and foundation should be constructed according to the manufacturer’s foundation drawings.

- After maintenance, it is crucial to ensure that all components of the ash calcium machine are adequately lubricated. Generally, if the ash calcium machine in a calcium hydroxide production line has been in use for more than six months since leaving the factory, the main shaft system, transmission, plate-beating device, and analyzer oil sump should be cleaned and inspected.